- An ISO 9001 : 2015 Certified Company

- info@narmadeshbrass.com

Infrastructure

Infrastructure

Manufacturing Facilities

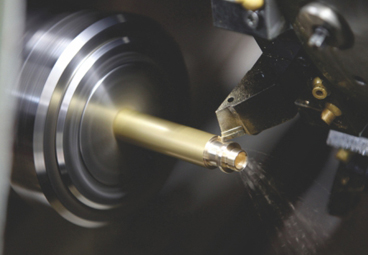

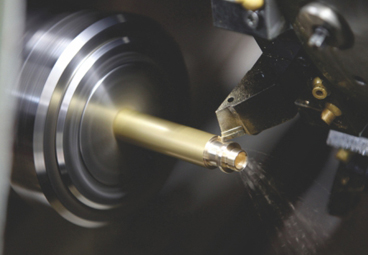

At Narmadesh Brass Industries, our commitment to excellence extends to our state-of-the-art infrastructure, which plays a pivotal role in delivering top-quality metal components and services. Our well-equipped facilities are designed to meet the highest industry standards and ensure the efficient production of a wide range of ferrous and non-ferrous metal components.

Our manufacturing facility is a testament to our dedication to precision and quality. With cutting-edge machinery and technology, we have the capability to produce customized metal components to exact specifications. Our team of skilled professionals operates in a safe and organized environment, ensuring the highest standards of production.

- Ultra-Modern manufacturing facilities and standards

- Experienced team of professionals

- Custom product manufacturing exactly as per drawing and sample.

Machining Capacity

- Machining of Ferrous & Non Ferrous Materials like Carbon, Stainless & Mild Steel, Aluminium alloys & Copper alloys.

- Machining jobs with batch sizes 5 nos. to 50000 nos.

- Core competence in Bar stock turning of any material.

- Machining of Hardened Steel up-to 50 HRC.

- Machining of Shafts(Turning, Keyway, Grinding & Burning etc.)

- Machining of Forging made of Mild, Carbon, Stainless steel, Aluminium & Copper alloys.

- Machining of Investment Casting, Sand Casting as well as Shell Moulding casting.

- Grinding external & internal up-to precision levels of 7 um.

- KAIZEN

- PPAP (Up-to Level 3), 5S